CHAPTER TWELVE

HOW TO REMOVE MOISTURE

There are several approaches that engineers typically consider to control a natatorium. This chapter highlights the two main approaches: refrigeration-based dehumidifiers and outdoor air ventilation systems.

It is important to understand the capabilities and limitations of each approach in order to select the best system for the application and climate. Energy consumption, geographic location, budget, and desired control of space conditions are among some of the key decision-making criteria.

KEY OPERATION FEATURES

There are two key operation features every dehumidifier should have to ensure the system provides the best comfort levels in the space while minimizing operating costs: maintain stable relative humidity levels and stable space temperature levels. Wide fluctuations of either negatively impacts patron comfort and system operation.

Dectron units with full ventilation/economizer capabilities optimize the use of outdoor air with a “ventilation forward” control strategy. This approach leverages outdoor air until operating the compressors is more economically beneficial.

A Dectron unit with compressors has a 0-100% modulating reheat coil whose control is based on the room air temperature trending. The control algorithm bleeds as much or as little heat as needed to essentially flat line the space temperature year round. Modulating reheat is important because for a vast majority of the year, the facility operates at off-peak conditions, and the system needs to be somewhere between peak cooling mode and peak heating mode. It is also important to note that when the room temperature is stabilized, the RH level will also be stabilized.

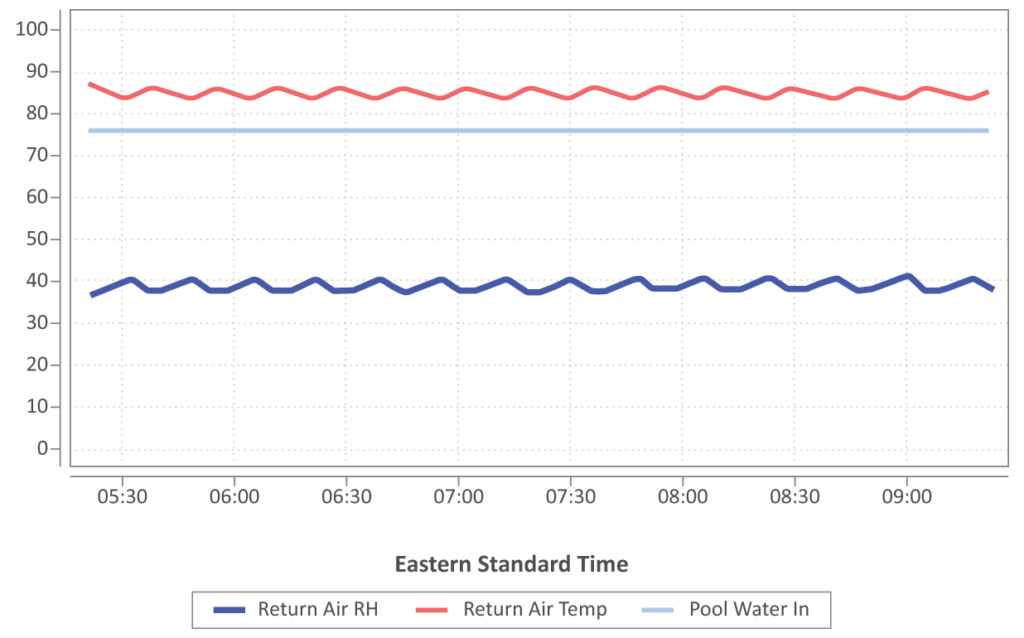

First, let’s look at a conventional compressorized unit with a hot gas reheat coil. Most hot gas reheat coils in pool units are on/off controlled, and this results in unstable space temperatures, which also results in RH level fluctuations. (The graphs on the following page are taken from Dectron’s performance monitoring technology for dehumidifiers.)

FIGURE 18: HOT GAS REHEAT COIL RESULTS IN UNSTABLE TEMPERATURES AND RH LEVELS

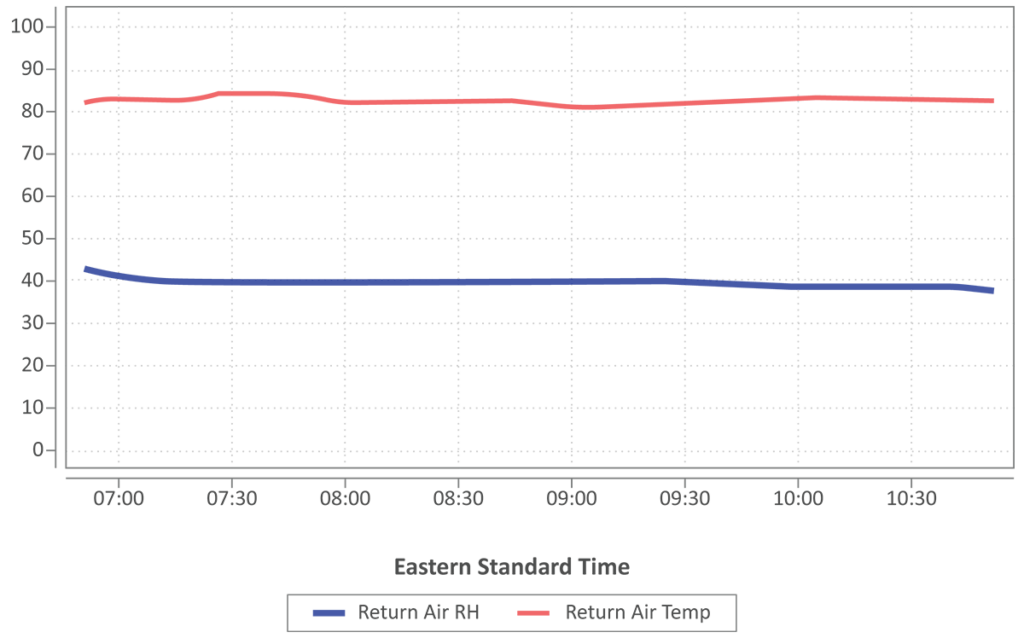

Now, compare this to a Dectron modulating reheat system. The space temperature is a flat line. This system provides better overall space temperature and humidity control, translating into better occupant comfort. This modulating approach to reheat also results in less wear and tear on the compressor as the unit does not have to cycle between on and off modes.

FIGURE 19: DECTRON’S MODULATING REHEAT SYSTEM PROVIDES STABLE TEMPERATURES AND RH LEVELS

REFRIGERATION-BASED DEHUMIDIFIERS

Refrigeration-based dehumidifiers are by far the most common and popular method of removing moisture from the space. These are the Dry-O-Tron LD/LEEDeR Series units built by Dectron. The units are designed and developed specifically for dehumidifying indoor pools, offering year-round humidity control at the lowest possible operating costs.

A major benefit of this approach is year-round humidity and temperature control with low operating costs. These systems use both sides of the refrigeration cycle (evaporator and compressor waste heat) simultaneously. Contrast this to traditional air conditioning units that use only the evaporator and dump condenser heat outdoors. These units use the evaporator to dehumidify (and cool when needed) but also put recovered heat energy back into the pool and/or back into the process air. This approach is unique to the natatorium industry. The system can be simultaneously dehumidifying (cooling) the air and reheating it (and/or the pool water) to deliver dehumidified and reheated air to the space and warm water to the pool. Not a single Btu on either side of the refrigeration cycle is wasted. Coefficients of performance are close to 8, and energy-efficiency ratios are greater than 25.

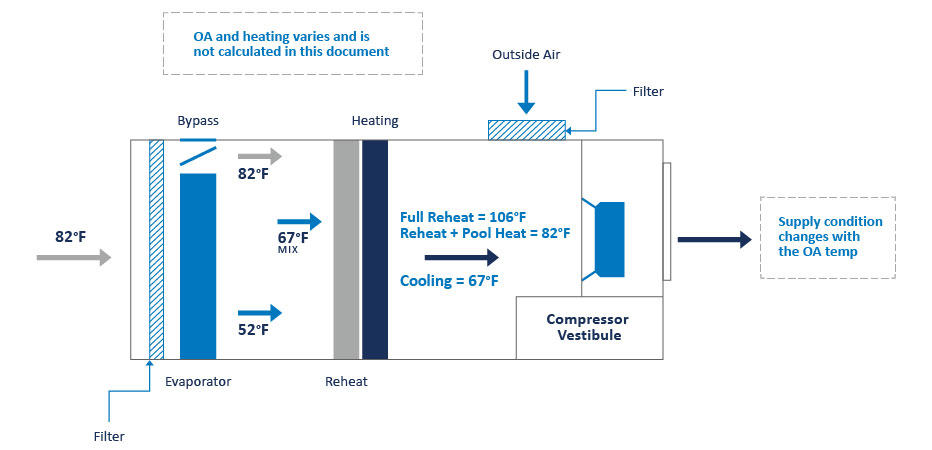

Figure 20 illustrates schematically how warm humid air passes through the dehumidifying coil and is cooled to below its dew point. Once air is cooled below its dew point, moisture condenses out of the air. Depending on the space temperature requirements, the hot gas from the compressor can be used to reheat the air or be rejected to an outdoor condenser. Compressor hot gas can also be used to heat the pool water.

FIGURE 20: REFRIGERATION-BASED DEHUMIDIFIERS

Pool water heating not only contributes considerable energy savings, but it also helps the unit operate more efficiently overall. This generally has a tremendous return on investment that alone should make it worth considering. Dectron provides an auxiliary pool water boiler to handle all pool water heating needs.

REFRIGERANT REDUCTION: DECTRON'S DRY-O-TRON LD/LEEDeR SERIES

The Dry-O-Tron LD/LEEDeR Series has become the HVAC industry’s new benchmark for indoor swimming pool dehumidifier technology. Compared to traditional all-DX units, the Dry-O-Tron LD/LEEDeR Series reduces annual operating costs by 5-7% and reduces the system refrigerant charge by upwards of 85%.

Dectron’s Dry-O-Tron LD/LEEDeR Series substitutes, Dectron’s Dry-O-Tron LD/LEEDeR Series substitutes hundreds of pounds of refrigerant with glycol, which is 95% less expensive and an environmentally-preferred heat transfer fluid for LEED© and other sustainable building projects.

All-DX systems have outdoor condensers and hot gas reheat coils that flood with liquid refrigerant for extended periods. The result is a large system charge, which aside from being expensive, creates the tendency for oil migration and premature compressor failure. The Dry-O-Tron LD/LEEDeR Series’ heat exchangers instead transfer refrigerant heat to the glycol loop, which is then used for air reheat or heat rejection to outdoor air cooled dry coolers.

The result is greater system reliability and reduced project costs. Not only is there a huge savings in refrigerant charge, but there are also additional installation cost savings because external PVC glycol piping to dry coolers is less expensive to install in labor/materials than copper refrigerant piping. The dry cooler system also has reduced likelihood of refrigerant leaks and longer compressor life, which further reduces lifetime cost of ownership.

It should be noted this technology is not new. Dry coolers have been employed in precision computer-room air-conditioning systems and environmentally-sensitive areas for decades.

At the moment, Dry-O-Tron LD/LEEDeR Series units are offered starting at 20 HP, but all Dectron units can be provided with the dry cooler heat rejection option.

Dectron’s innovative heat rejection design makes the Dry-O-Tron LD/LEEDeR Series equally efficient as DX systems on summer design days and 5-7% more efficient throughout the rest of the year. The innovative fluid design uses an active refrigeration head pressure monitor/control that ensures the lowest possible condensing pressures to boost system performance year round.

Other benefits of the Dry-O-Tron LD/LEEDeR Series include the following:

Fully modulating, total variable reheat provides the ultimate indoor air comfort by providing unprecedented stability in pool space temperature and relative humidity levels.

- Factory-charged and sealed refrigeration system means no on-site field charge refrigeration work or EPA-certified installation technicians are required.

- Small factory-sealed refrigerant charges totally eliminate all issues of refrigerant and oil migration associated with all traditional DX systems.

- Significant reduction of system refrigerant charges prevent costly service costly service bills in the event of a refrigerant leak.

- Package or split system and indoor or outdoor configurations are available with no distance limits between the unit and the AC heat exchanger.

- Glycol is 95% less expensive than refrigerants, thus any recharging service costs are significantly reduced in materials and labor.

- No copper piping between the unit and remote condenser eliminates temptation of material theft.

- All critical components are located outside of the corrosive air stream in a protective service vestibule.

PADDOCK EVACUATOR INTEGRATION

Dectron’s Dry-O-Tron LD/LEEDeR Series is fully compatible with the Paddock Evacuator source capture system (www.paddockevacuator.com ), an essential technology for reducing chloramines and delivering good indoor air quality.

OUTDOOR AIR VENTILATION SYSTEMS

Ventilation-based dehumidification is an established approach that uses fresh air to dry the space. This approach to dehumidification is possible in areas with suitable climates that are dry and/or cool outdoors year round and has been used successfully for decades. A cooling coil is sometimes added when the conditions might be warm in summer.

These outdoor ventilation style units have several attractive features if the facility is located in a suitable geographic area. They have a lower first cost than a refrigerant-based approach and are also considerably simpler units operationally. With heat recovery between the exhaust air and outdoor air streams and controls that properly sequence the outdoor air, this can be a very attractive means to ventilate a natatorium.

THE HYBRID SERIES

The Dectron Hybrid design provides the simplicity, reliability, and efficiency of ventilation-based dehumidification for indoor pools, along with heat recovery and an optional cooling coil to provide air conditioning if required.

While the Hybrid Series is a suitable dehumidification solution for indoor pools in most North American climates, it is most cost-effective in areas where outdoor air is dry for most of the year. However, unlike other ventilation-based dehumidifiers, the Hybrid Series also provides sensible cooling capability, so high outdoor air temperatures are no longer a concern.

The Hybrid Series offers the following advantages:

- Its simple design makes it easier to service and maintain; smaller refrigeration components cost less to operate and maintain.

- Mechanical cooling keeps the space temperature comfortable by meeting the sensible load.

- Advanced control algorithm precisely modulates outdoor air, using only the minimum necessary to maintain space humidity.

- Direct-drive fan array with ECM motors means lower energy costs and no belts!

- Heat recovery standard with Dectron’s energy efficient glycol runaround loop that dramatically reduces the cost of pre-heating outdoor air.

The Hybrid Series is available with the following options:

- Unit-mounted, EC motorized exhaust fans

- Purge mode

- Packaged space heating – hot water, electric, or gas furnace

TABLE 7 – SYSTEM COMPARISON

| REFRIGERATION | OUTDOOR AIR VENTILATION | |

|---|---|---|

| Operating Cost | Lowest | Medium |

| First Cost | 100% | 80% |

| Year-Round Humidity Control | Yes | Weather Dependent |

| Meets/Exceeds Energy Standard 90.1 | Yes | No |

| Dehumidification Energy Recovery | Yes | No |

| Heat Recovery on Exhaust and Outdoor Air | Option | Option |

| Cooling Mode | Yes | Extra |

| Pool Water Heating | Yes | No |

WEB MONITORING WITH VISION 2.0

Web monitoring is a powerful humidity control technology that allows users to monitor and precisely fine tune natatorium conditions from a computer, tablet, or smartphone.

WebSentry from Dectron delivers incomparable value and peak performance for the lifetime of the dehumidifier – and it’s installed at no cost on every Dectron unit. Nothing more than an Ethernet connection is all that’s required to take full advantage of WebSentry (Wi-Fi and cellular network options are also available).

Once connected, WebSentry connects securely with Dectron’s remote servers and begins sending performance data every 60 seconds, 24 hours a day, 7 days a week – for the ultimate in performance monitoring.

WebSentry offers the following advantages:

- Peak Performance – With WebSentry, the same engineers who designed and built the dehumidifier can remotely observe, control, and fine-tune its performance during and after installation with control of over 100 critical functions.

- 24-7 Remote Monitoring – WebSentry allows Dectron’s servers to remotely monitor, record, and analyze the dehumidifier performance every 60 seconds, 24 hours a day, 7 days a week, providing real-time online data access for operators and authorized service technicians.

- Remote System Control – WebSentry allows authorized technicians and service experts to remotely view and change performance parameters in real time via any Internet-connected device, including smartphones.

- Performance Trouble Alerts – WebSentry provides instant email alerts to key personnel should any system parameters not conform to performance expectations.

- Maintenance Reminders – WebSentry helps ensure scheduled maintenance to maximize performance, boost energy savings, and provide the absolute lowest overall cost of ownership of any dehumidifier in the industry.

Having a unit connected to WebSentry is like having Dectron keep an eye on it, alerting service personnel to any possible issues. That’s why WebSentry connection at startup is highly recommended.