Dry-O-Tron Dry Coolers

Premium Performance – Exceptional Efficiency

Outdoor Dry Coolers from Dectron are an ideal solution for your medium and large-scale fluid-cooled heat rejection needs. Our Dry Coolers use superior components and design to deliver a better heat rejection system available in capacities from 116 MBH to 2,300 MBH.

- Heat rejection capacity from 116 MBH to 2,300 MBH.

- Fully-dipped coils:

- Ultimate corrosion protection and longevity with 3,000 hour salt spray rating.

- Special coating makes the coils virtually self-cleaning.

- EC motor fans controlled on 0–10vdc signal for

maximum cooling performance with minimum

energy consumption.

- Very low maintenance motor.

- Capable of higher pressure drops.

- Variable fan speed based on leaving fluid temperature control.

- Fan blades designed for quiet and efficient air movement.

- The “V” configuration allows larger coils and higher airflows in the smallest possible footprint.

- Lightweight and compact for easy handling and flexible installation.

- Twin four-row coils with the latest tube and fin technology provide maximum fluid heat rejection and durability.

- Very low internal fluid pressure drops further help reduce pump operating costs.

- PVC ANSI raised flanges make fluid connections easy.

- Fluid-cooled systems are inherently environmentally friendly because of their low refrigerant charge.

Dectron Dry Coolers are ideal for any application

where medium to large-scale fluid-cooled heat

rejection is desirable. Some examples:

- Facilities where full cooling is needed during low- ambient conditions, e.g. data centers.

- Fluid-side economizer on chillers.

- Supplementary A/C heat rejection on ground- source heat pumps and geothermal wells.

- Any medium to large-scale A/C application.

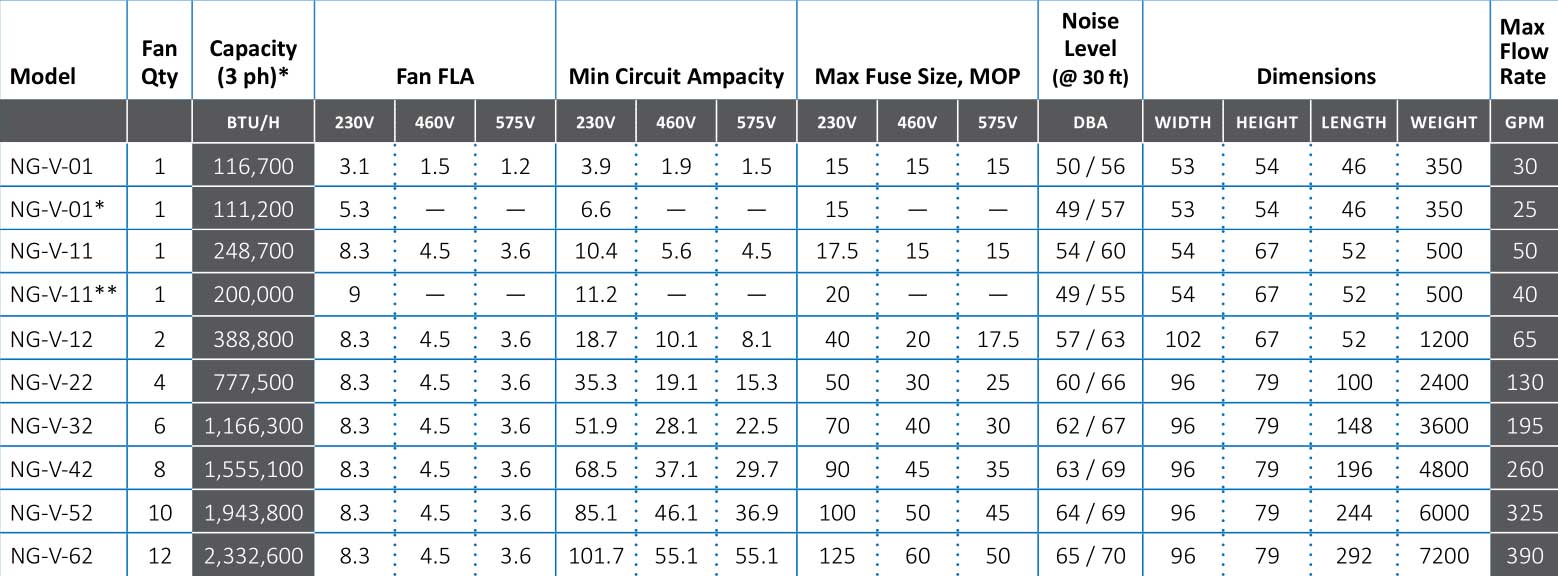

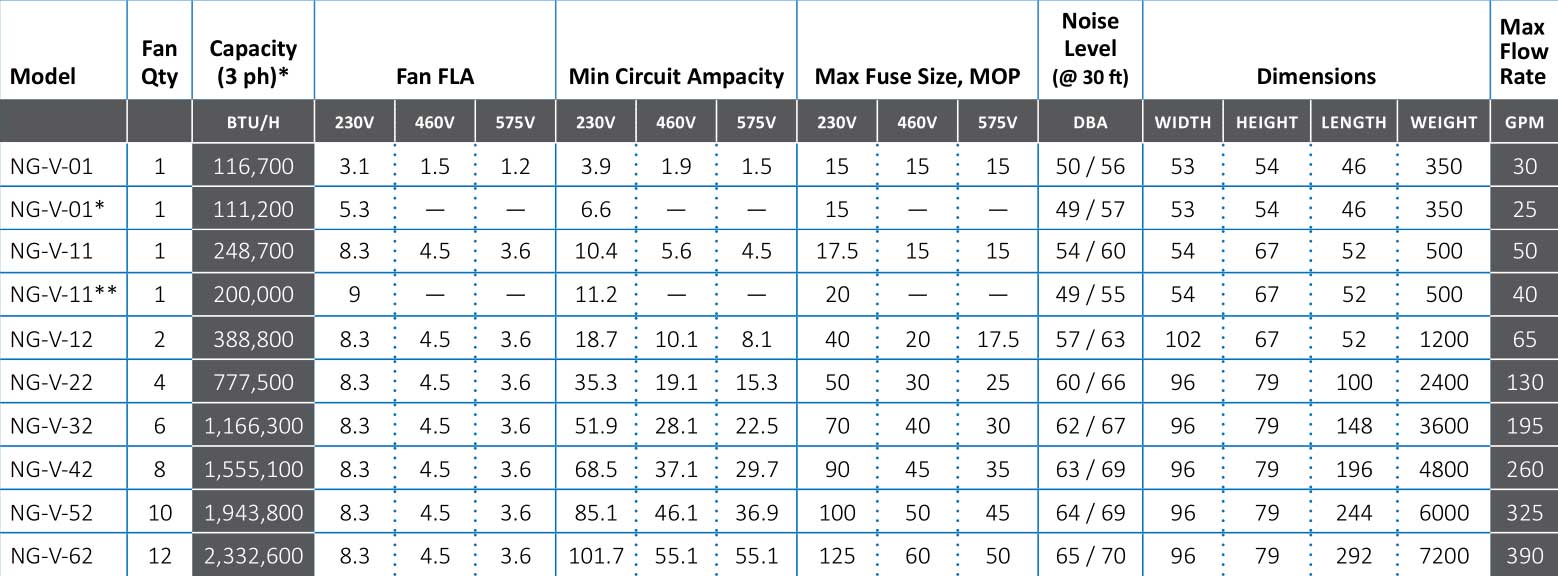

Performance Data Without Pump Kit

*Single phase model. **Single phase, fan motor w/ VFD. Lower sound level for 75% load. Rated conditions: 100°F air-on, 125°F entering fluid, 35% propylene glycol at unit max flow. E&OE — Subject to Change Without Notice.

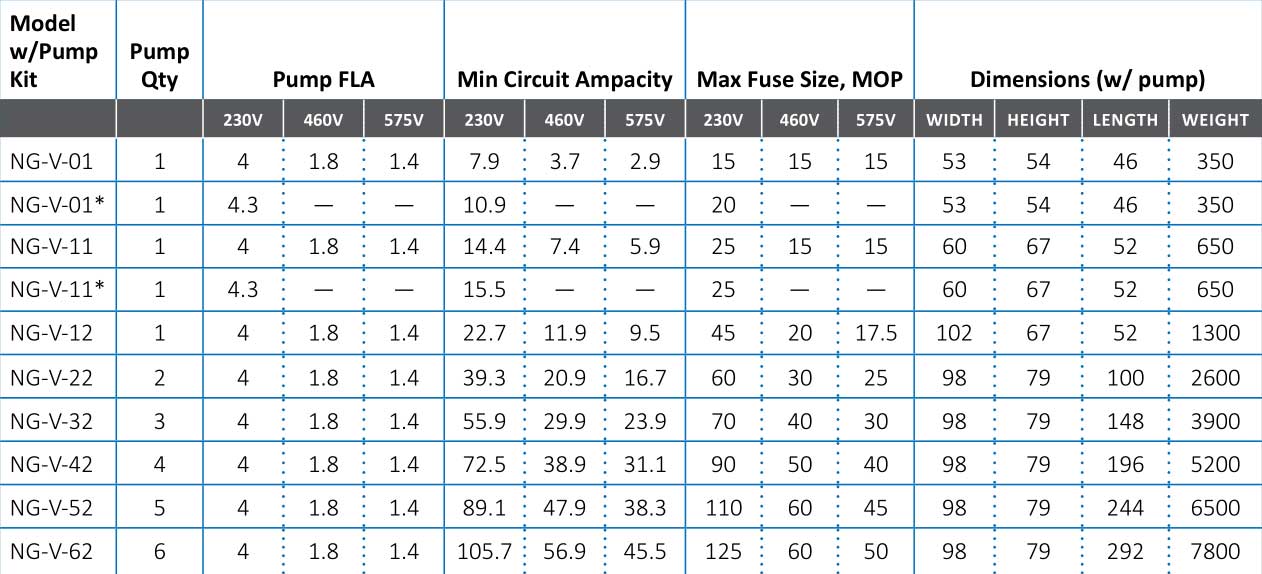

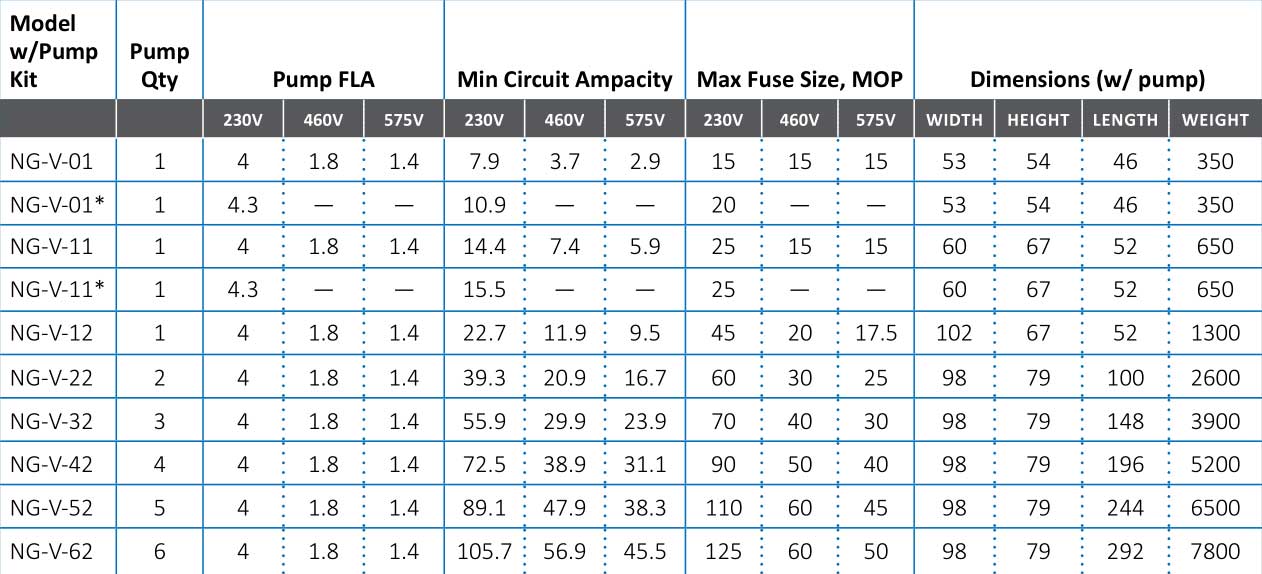

*Single phase model. Units with pump kit have same capacities, flow rate, fan FLA and noise levels.

Performance With Pump Kit

- Packaged pump kits

- Unit mounted disconnects

- Factory-provided aquastat to generate signal that controls fan speed to leaving fluid temperature.

- Available voltages are 208-230, 460, 575 VAC, three phase (some models also available in single phase)

- Fully-dipped coils:

- Ultimate corrosion protection and longevity with 3,000 hour salt spray rating.

- Special coating makes the coils virtually self-cleaning.

- Direct-drive fans with EC motor or VFD vary speed for precise control of fluid temperature at lowest possible electricity cost.

- Fan blades designed for quiet and efficient air movement.

- The “V” configuration allows larger coils and higher airflows in the smallest possible footprint.

- Lightweight and compact for easy handling and flexible installation.

- Twin four-row coils with the latest tube and fin technology provide maximum fluid heat rejection and durability.

- Very low internal fluid pressure drops further help reduce pump operating costs.

- PVC ANSI raised flanges make fluid connections easy.