Dectron Units are the Future of Dehumidification

Ingenious Innovation

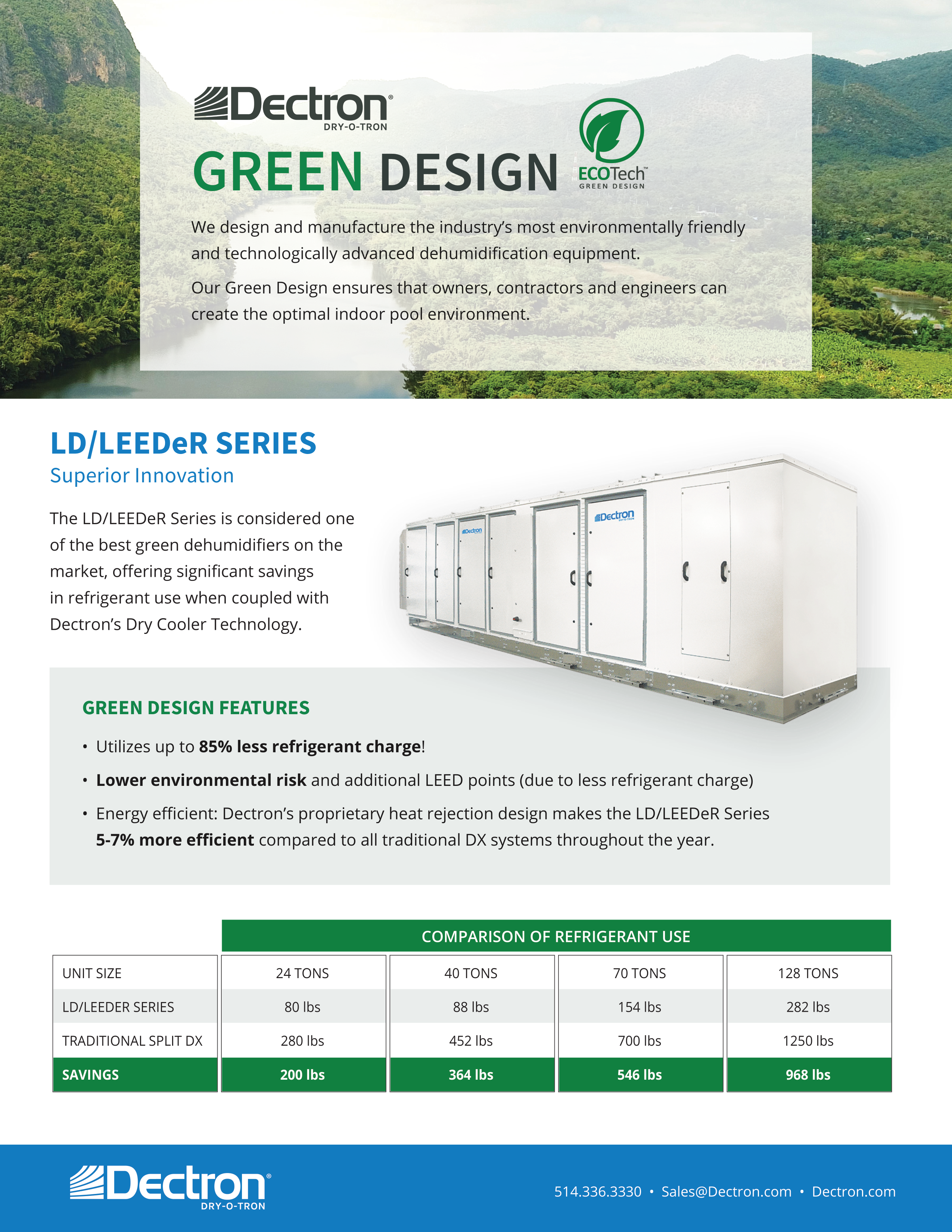

Dectron‘s revolutionary Dry-O-Tron LD/LEEDeR, the biggest industry innovation in 20 years, is the future of dehumidification. In large pools, traditional dehumidifiers require a large refrigerant charge that is not just expensive, but also leads to system migration challenges that can impact compressor reliability.

Solves Traditional Challenges

Traditional refrigerant split systems also severely restrict in distance between the unit and its remote condenser. Our ingenious Dry-O-Tron LD/LEEDeR overcomes both of these issues and more, through the use of a water/glycol mix as a secondary heat exchange fluid. Moreover, our Dry-O-Tron LD/LEEDeR also provides superior humidity control, exceptional reliability and lower operating costs, with as little as 1/6 the traditional refrigerant charge.

High Capacity Dehumidification

For applications requiring from 110 to 765 lbs per hour of moisture removal or 6,000 CFM to 64,000 CFM of air handling, our Dry-O-Tron LD/LEEDeR beats the competition hands down – in every design consideration, every time! The Dry-O-Tron LD/LEEDeR is also designed to integrate with and provide maximize performance with the Paddock Evacuator chloramine removal system.

- The ultimate in stable indoor air conditions through fully modulating reheat

- Up to 85% less refrigerant charge — completely factory sealed

- No on-site refrigeration work required to install

- Less cost to install and maintain

- Compliant with ASHRAE Standards 15 and 34

- No seasonal refrigerant and oil migration issues

- Decreased risk of compressor issues

- Increased performance

- Water-cooled design means outdoor heat exchanger can be located far from unit

- Heat exchanger can use PVC instead of copper

- 5% to 7% more energy efficient than split-DX systems

- WebSentry Internet monitoring and control

- Touch screen SuperviseAire control systems

- Premium corrosion resistance

- Mechanical vestibule outside the air stream on all units

- Better system performance as vestibule avoids leaching heat from compressor and blower motor into airstream

- Many service tasks can be performed without interrupting operation

- Protects key components including compressor and blower motor from harsh airstream

Coming Soon

- Pool water heating

- Exhaust with heat recovery

- Smart Purge or Full Purge

- Air conditioning via dry cooler (split or packaged) or chilled water

- Auxiliary air heating (electric, hot water, steam or gas)

- Motorized outdoor air on/off damper tied to built-in 7-day time-clock

- Outdoor air ventilation built-in, complete with filter and manually adjustable damper

- Upgrade to MERV-13 outdoor filters

- Source Capture feature for optimal IAQ design

- WebSentry Internet monitoring and control

- Factory support via the Internet

- Performance monitoring, 24-7

- Full unit history stored online for simplified troubleshooting

- Trouble warnings via e-mail

- Smart phone access and control

- Unrivaled 1-year labor warranty with WebSentry connection

- 2-year warranty on parts

- SuperviseAire control system with optional touch screen interface

- The most sophisticated and powerful controller in the industry

- Integrated BACnet, LON and Modbus connectivity

- Service vestibule outside airstream – on all units

- Critical components outside of chlorinated air stream

- Maximum AC efficiency, no heat gain from warm components

- Easy to service even while unit in operation

- Direct drive fans, backward inclined airfoil plenum

- Quiet, powerful, efficient, reliable, energy efficient

- Higher static pressures

- Quieter operation and greater energy efficiency

- Allows for factory installed auxiliary air heating

- Offers maximum flexibility for supply air duct options

- No belts to adjust, wear out or replace

- Easier air balancing from controller or WebSentry.

- Fully dipped coils for 100% corrosion protection – not just the fins!

- Extraordinary compressor protection

- Refrigerant pressure transducers on suction and discharge

- 24/7 monitoring of critical suction and discharge pressures

- pump down, crankcase heater, voltage monitor

- suction accumulator, oil separator, oil monitoring

- Sight glasses on receivers for easy field charging of split systems

- Multiple compressor systems for staged control

- Flexible supply and return air openings – multiple openings also possible

- Mirror configurations available for all models to suit duct work requirements

- Best cabinets in the industry

- 2-inch insulation

- Double wall construction, door holders

- Rain-guards over the doors

- Water-cooled design — reject heat to dry coolers or chilled water.

- Roof curb or slab compatible base design

- MERV-13 filters return air filters